Mass Timber: An Annotated Bibliography

Following up on my previous Carbon Removal reading list, I’ve also spent several months at Actuate Innovation studying mass timber, particularly in the US context. I’m sharing some of the resources I found useful for anyone interested in learning more about mass timber.

Again, views expressed here are strictly my own and do not necessarily represent the views of my employers. Anything linked here is not necessarily an endorsement.

A quick summary for those who aren’t familiar with mass timber:

Mass timber is a new building technology that uses wood composites to build mid-rise and high-rise buildings.

The benefits of mass timber include improved aesthetic, reduced construction time, and more modular construction. Issues like fire safety and earthquake safety have already been resolved - in many ways, mass timber is actually safer than concrete buildings, because wood chars on outer layers, providing a protective layer.

For the climate angle, mass timber is more sustainable than concrete and cement with lower lifecycle emissions, helping to decarbonize buildings

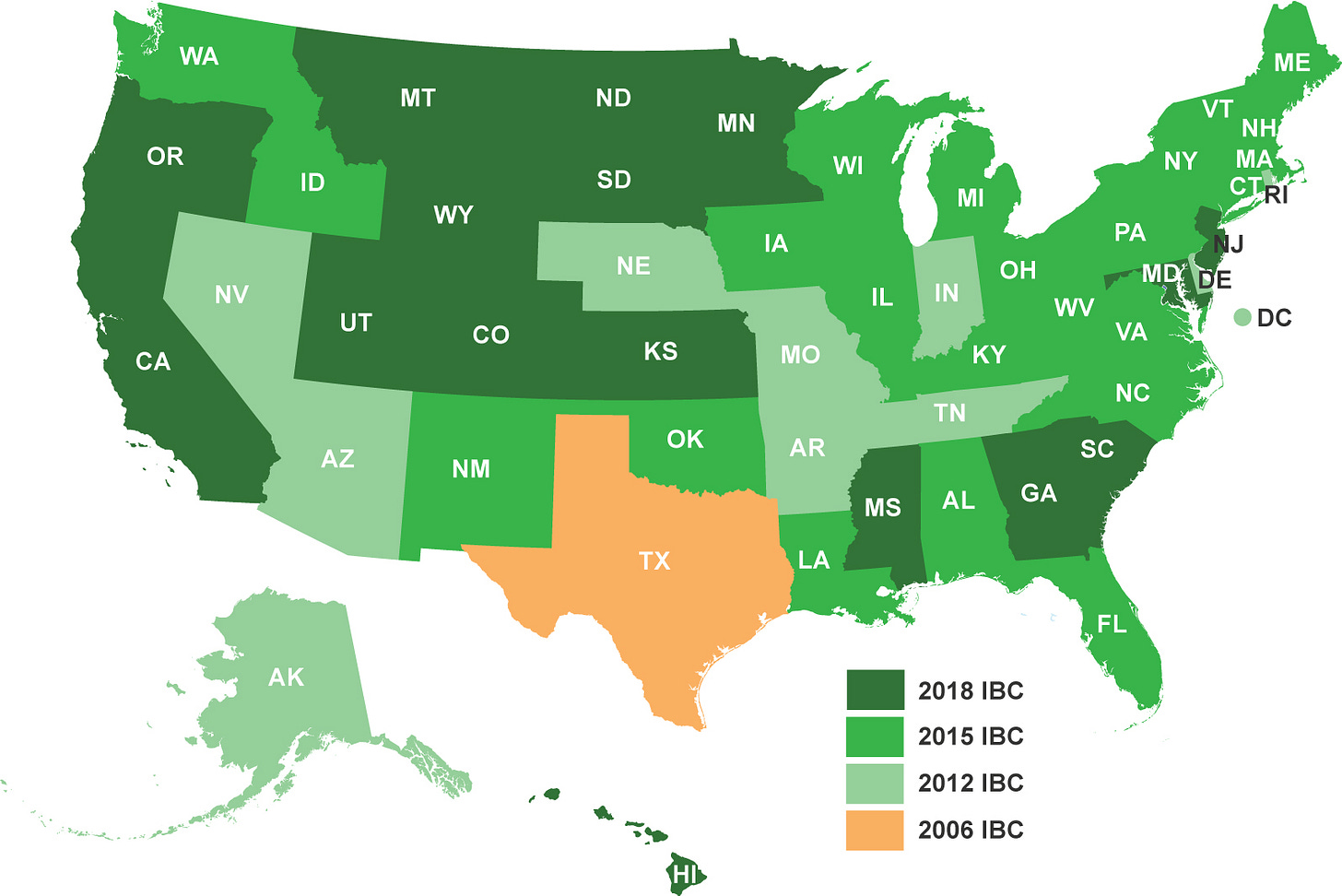

A rough summary of challenges to adoption: lack of updated building codes (the most recent 2021 IBC allows mass timber up to 18 stories, but most jurisdictions haven’t updated their building codes yet, see below), contractor unfamiliarity drives up bid-cost and construction delays, and lack of domestic mass timber supply chain

Level 0: Introduction

Vox Mass Timber Explainer (2020) by

ConstructionDive’s Mass Timber 101 (2017)

A more architectural/engineering primer on Mass Timber by Canadian Architect (2019)

Level 1: Building Codes, Lifecycles, and Trees

WoodWorks is a non-profit that provides excellent technical resources on Mass Timber. This set of compiled business case studies in Mass Timber provides first-hand accounts on the challenges to building mass timber. Common challenges include

fire marshall skepticism

long permitting timelines in western states like California

high insurance premiums

first-of-a-kind regulatory friction with building code approval

Building code adoption in general is fragmented and lagging:

For those who prefer video, this is a nice overview of mass timber in the southeast US:

Lifecycle Analyses

(2020) Comparative LCA of Mass Timber Buildings and Concrete Alternatives. From US Forest Service Researchers, who studied a 12-story mixed-use building Portland

embodied carbon: mass timber had 18% lower CO2-eq emissions than concrete

operational energy carbon cost: mass timber had 7% higher energy use than concrete, but comparable usage of fossil fuels for energy (due to time variability of power grid generation sources)

(2022) A Lifecycle Assessment of a Low-Energy Mass-Timber Building and Mainstream Concrete Alternative in Central Chile. Studied a mid-rise residential building with mass timber vs concrete over a 50-year cradle-to-grave:

embodied carbon: 131 kg CO2-eq/m2 (compared to 353 kg CO2-eq/m2 for concrete)

operational energy carbon cost: 31 kg CO2-eq/m2 (compared to 187 kg CO2-eq/m2 for concrete)

(2019) Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA based comparative case study in the U.S. Pacific Northwest. From University of Washington in Seattle, this study looks at an existing 8-story office building in Seattle:

embodied carbon: mass timber has 26% lower CO2-eq emissions

operational energy carbon cost: mass timber has comparable energy usage, but 8% lower carbon emissions from energy, again due to time-variability of generation

On balance, mass timber has at least 20% lower CO2-eq emissions and possibly marginally lower operational energy cost. Given the existing cost premium of mass timber in the US and the barriers to adoption, why care about this technology?

My thesis is that biomass utilization is actually underrated as a climate solution because biomass is inherently net-zero. Building with mass timber is literally building with free carbon dioxide from the atmosphere. Decarbonizing concrete and steel requires significant new technology, which we should of course also invest in. But it would be foolish to ignore or not expand this existing technology that has carbon removal, utilization, and recycling built into it. There’s also arguably some second-order effect: by driving up demand from mass timber in construction, you increase the value proposition for increasing supply of lumber through reforestation.

What about the Trees?

Of course, anytime you bring up anything to do with trees, people will say that you hate the environment because you’re cutting down trees (ignoring the fact that most deforestation is actually driven by cattle). So I also looked at forestry stocks in the US and how mass timber might affect them.

(2022) Increasing Mass Timber Consumption in the U.S. and Sustainable Timber Supply, by 3 University of Washington Seattle researchers. Here’s their conclusion on what would happen to US forestry stocks if mass timber increases lumber demand:

Using USFS FIA data, incremental U.S. softwood timber harvests were projected that would be necessary to supply the Softwood Lumber Board’s high-volume estimate of mass timber and light framing consumption in 2035. Growth in reserve forests and riparian zones was excluded, and low confidence intervals were used for growth estimates, compared with high confidence intervals for harvest and consumption estimates (i.e., the most conservative scenario). Results were considered for the U.S. in total and by three geographic regions (North, South, and West). In total, growth exceeds consumption including the incremental mass timber volumes. On a regional basis, growth exceeds consumption in the South and the North, but under these very conservative assumptions, consumption could exceed growth in the West region by around 10%.

…

Our results are not particularly surprising to anyone familiar with U.S. forest inventory data and the history of the U.S. timber supply. It is a well-known fact among forestry professionals, the forest products industry, and related academia that the U.S. timber supply has been expanding for over half a century. However, this is not well known outside those circles. Cognitive dissonance related to a desire to use wood building products for their carbon storage capability but concerns about sustainability is understandable. The results of this research add more evidence that should help allay those concerns. Our analysis clearly shows that the United States can sustainably use more mass timber and reduce greenhouse gas emissions and embodied carbon in our built environment.

(2014) US Forest Service Resource Facts:

Total forest coverage in the US has been stable/increasing for 50 years, while population has also increased

Even though total forest area has stayed constant for 50 years, the US has been a disproportionately productive lumber producer:

Clearly, environmental regulations and prudent logging practices like forest rotations have resulted in both commercially productive lumber industries while maintaining carbon biomass and protecting American forests

(2021) US Forest Ownership and Management, Congressional Research Service. When thinking about forestry and barriers to increasing lumber supply, it’s also useful to understand forest ownership, which varies significantly by region

Level 2: Supply Chains and Demand-Pull

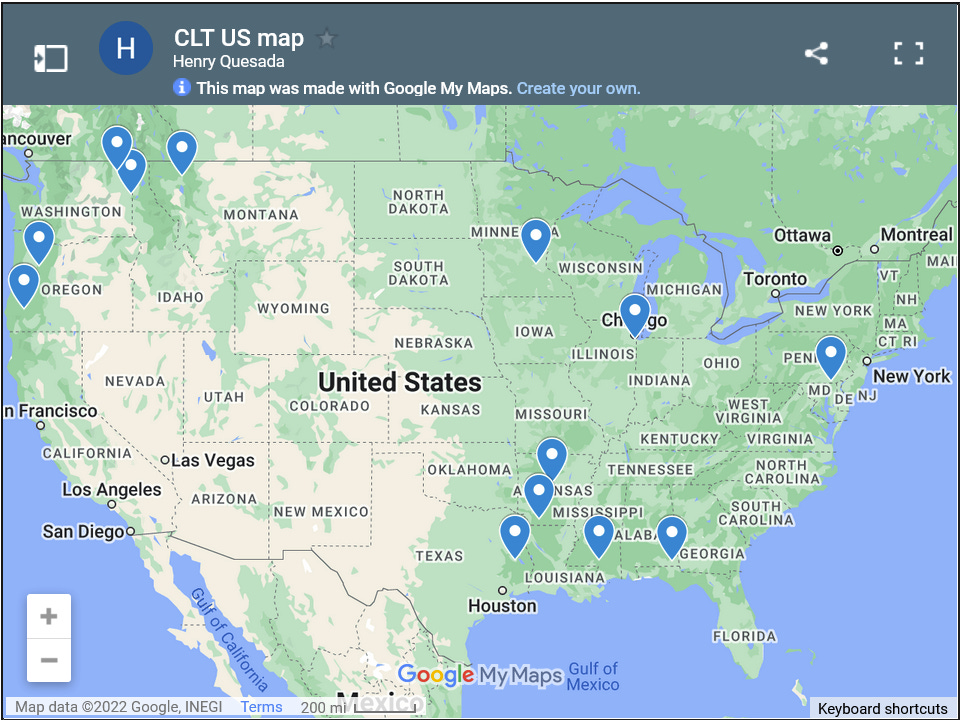

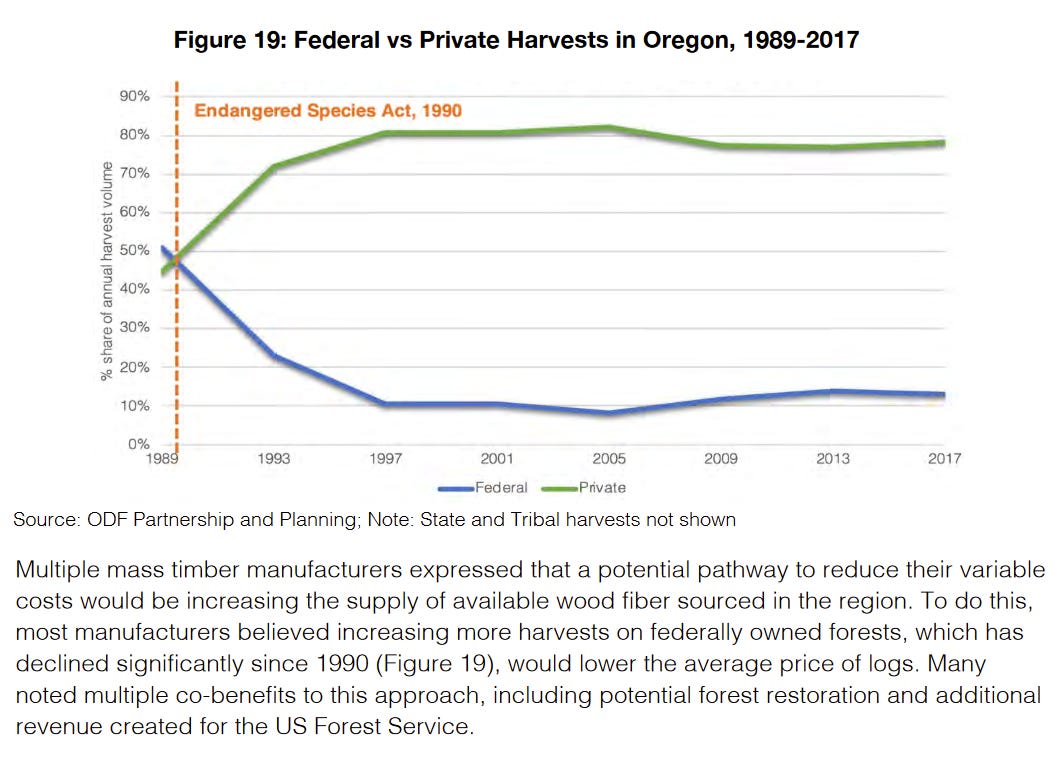

(2020) Identifying Drivers and Barriers for Investment in Oregon’s Mass Timber Manufacturing Supply Chain. An excellent deep-dive into the actual manufacturing process for mass timber, a state-level analysis of political and economic considerations for driving adoption of mass timber, and good nuggets on different supply chain issues.

(2018) Mass Timber Market Analysis. A bit out of date, but Oregon also commissioned a market analysis from the Beck Group.

(2019) Mass Timber Cost Review. British Columbia also commissioned a study on mass timber cost breakdowns and how to reduce the cost premium

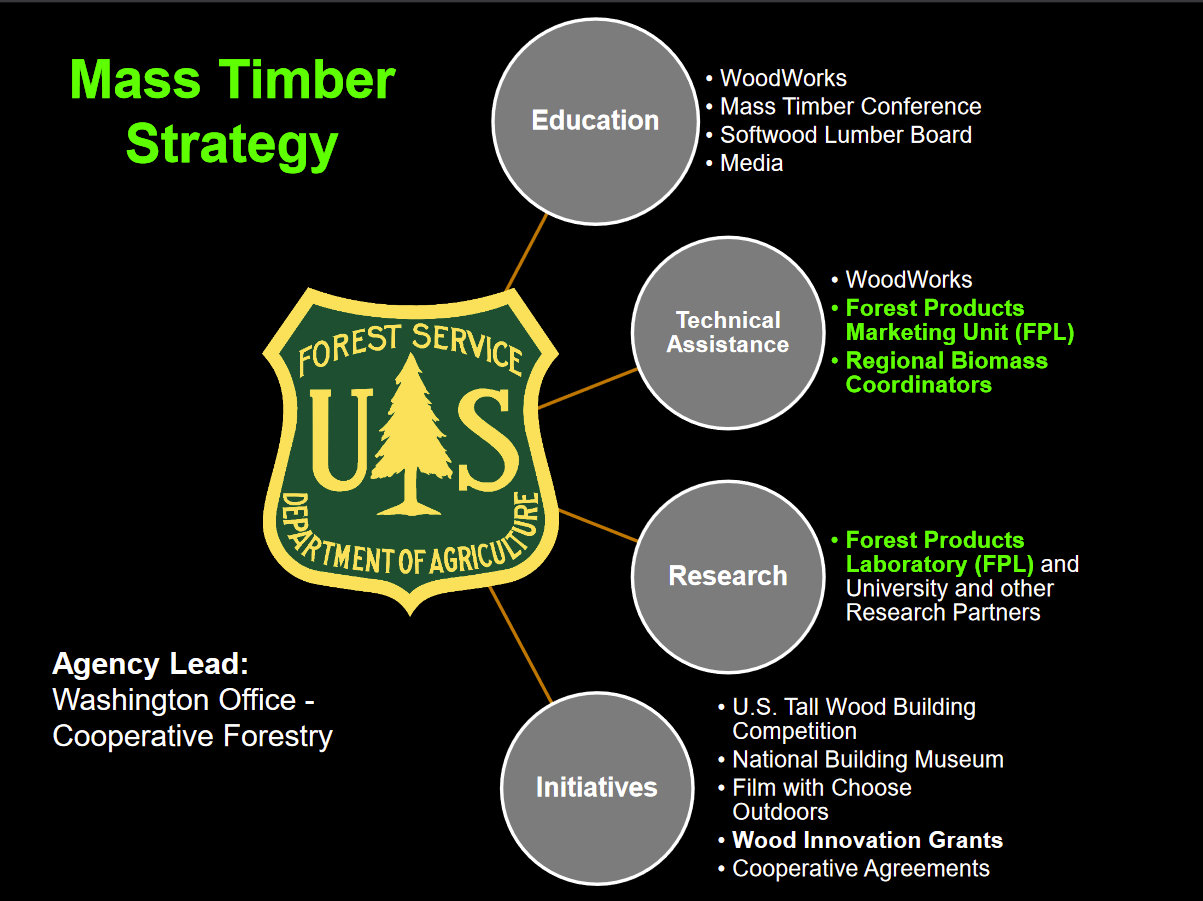

(2017) A slide deck overview of US Forest Service involvement with Mass Timber

(2022) The Beck Group also produces an annual mass timber report you can access for free

Mass timber is a complex system because understanding how buildings are built require grasping local zoning, state building code adoption, and national standards, while also understanding the supply chain and labor skillsets. The construction and real estate industries also tend to be more opaque than say software or physics, so I’m still learning more about how the market conditions they operate in (and might write up some more of my learnings along the way). Here are 3 useful sources I would recommend if you’re interested in learning more context about how things are built:

- by (just read the whole thing from the beginning)

ConstructionDive - great industry newsletter

NotJustBikes on Youtube produces great content on zoning and urban design